Higher efficiency

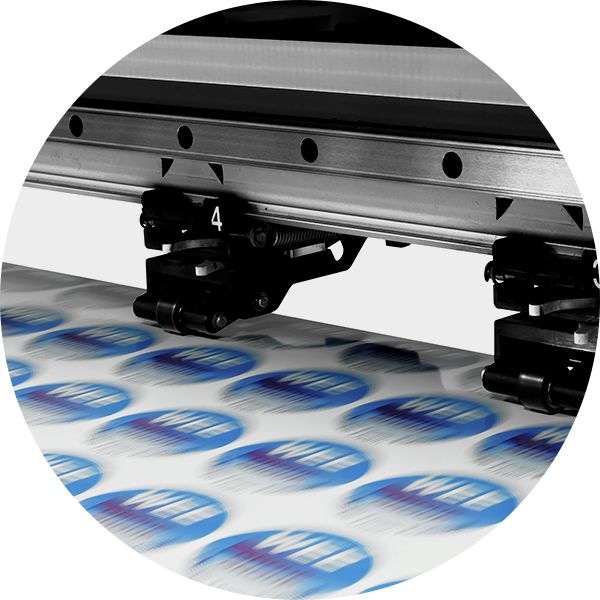

in wide format digital printing

Wide format digital printing with a holistic end-to-end workflow

What is wide format printing?

The history of wide format printing is very short, having only emerged since the end of the 20th century. Especially the digital orientation, above all inkjet technology, has developed enormously in the last 15 years. The pioneers were HP and Canon collectively. Currently there are several technologies used, the newest one is Latex (used as ink type) and UV-Gel. The large sheet format and the high variability in terms of substrates enable all the following products to be manufactured in wide format printing

OneVision's Software Wide Format Automation Suite can be applied for a wide range of products to be printed on various substrates: foil, paper, vinyl, acrylic, photo wallpaper, PVC, wood, hard foam boards, canvas, and much more...

No matter what substrate, the Software Suite for wide format printers helps you to print more efficiently, making maximum usage of your substrate, minimizing wastage, in a semi-automated or fully automated fashion – as a holisitic end-to-end workflow!

Wide format digital printing – the main challenges

- tight customer deadlines

- long make-ready times

- manually set-up of files such as preflight, normalization

- generate bleed, nesting/ganging, cut line

- machine idletimes

- files getting rejected by the RIP due to transparencies

- file complexity, missing color management, etc

- seasonal peaks

- increasingly shorter print runs

Do your customers order predefined products (web shop)?

- check incoming files automatically

- workflows based on metadata, barcodes or jobticket

- automatic preflight, detecting and fixing file-errors

- automatic sending of the normalized data file for approval

- automatic nesting/ganging

- automatic cut line/cut file generation

- connection to all third-party machines of your system landscape

The Wide Format Automation Suite is tailored to your needs!

In all these cases our Wide Format Automation Suite is the suitable software for you. It is tailored to your workflow and your needs.

Deon Capogreco, Managing Director Big Image Australia“OneVision has allowed us to process files faster and more accurately than ever. We have only just scratched the surface of what is possible.”

Intelligent workflow management

According to your required parameters (individual machinery), your own assembly lines are configured for the file workflow. Incoming files through e-mail, hotfolder, FTP, web server, etc. are automatically downloaded and linked to the XML order data of your ERP system (any manufacturer) and the job ticket is available.

The OneVision Workflow Management System can easily standardize, automate and control your production processes.

Comprehensive file optimization

The 11 most important and common PDF problems are solved and nothing stands in the way of smooth production.

E.g.: Preflight, Normalization, Color Management, Identifiable errors automatically corrected, Generate bleed, Flatten transparencies.

File formats that are larger than the maximum print format can be automatically tiled/paneled and split into multiple formats for production.

Print form creation and finishing preparation

High-quality substrates are utilized to the maximum by the unique nesting technology. The OneVision software evaluates all variables, analyzes the print jobs in the queue and determines the best combinations to maximize printed areas and eliminate as much sheet waste as possible. Of course, file size gets optimized.

The completely automated solution: reduces waste to an absolute minimum – positions single layouts to complex shapes – maximizes material usage – creates a separate PDF with the cut lines only – and sends that PDF straight to the cutter. More about nesting

Extensive integration options

After the print file has been automatically prepared for printing and finishing (cross-job nesting, tiling, paneling, creation of crop marks e.g. eyelet marks, hemstitching...), the workflow management system sends the created print file and finishing file to the RIP/DFE or production machines so that production can be started. Take a closer look at our range of connectivity

Do you also have diverse products and numerous production lines with individual parameters? All the better! Then the Wide Format Automation Suite can play all its trump cards!

The four core components of your wide format digital printing workflow:

Your benefits

- error-free print & finishing files

- bottleneck in prepress resolved

- no machine idletimes

- reliable adherence to the delivery promise

- shorter delivery times due to shorter production times

- modular software, customizable to your needs

- integration into existing system landscape

- cost savings in production: trouble-free and sustainable (no reprints, minimize manual touches, maximum substrate usage)

- significantly higher productivity and efficiency gains thanks to your defined degree of automation

- increasing customers satisfaction & loyalty

Michael Hiemann, Managing Director Siepro KG“Not only have we increased the number of jobs per day – we've also improved our profit margins. Using the Suite allows us to work significantly more flexibly, saving time and costs.”

Markus Maier-Schambeck, Managing Director medienkraftwerk GmbH“Since the introduction of OneVision Software, our production preparation runs so silently that we are only alerted to the fact that production is running at full speed by the sound of the shipping label printer.”