Nesting Software

sustainably used substrate

Nesting software/gang run printing – saving material, time and costs.

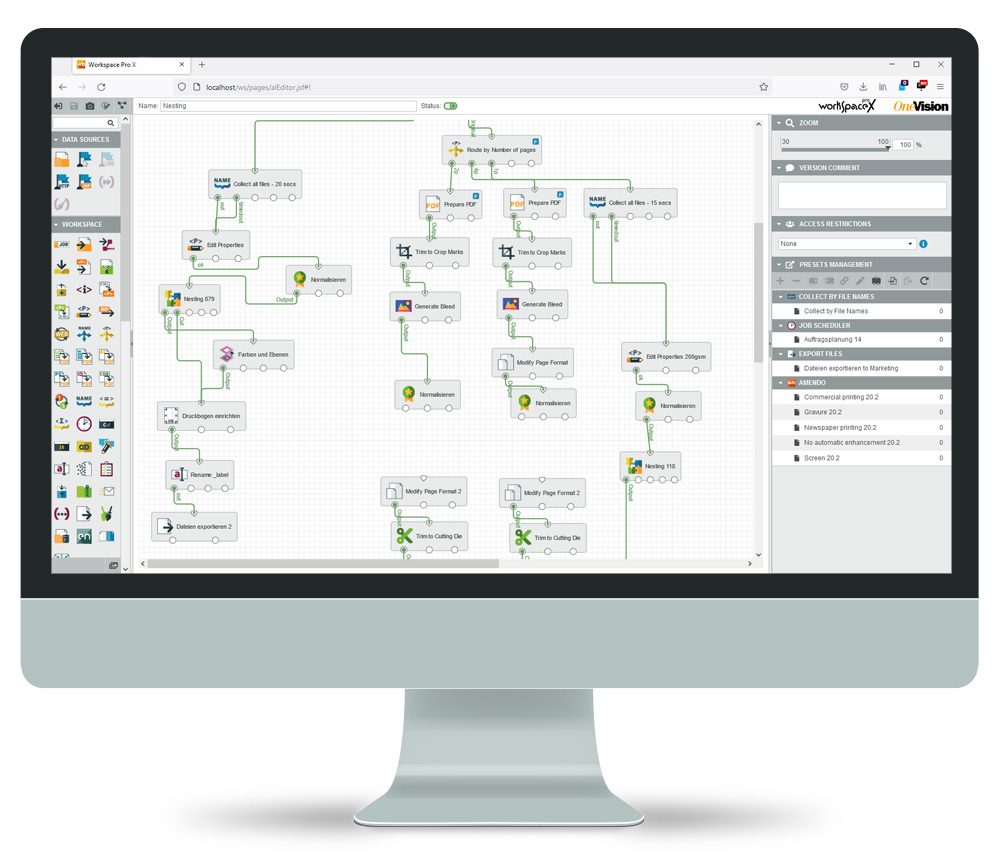

Complex print jobs, a variety of materials, low quantities and high deadline pressure. Those who want to maintain an overview and, above all, profitability, rely on OneVision's fully automated nesting software/gang run printing software. Thanks to powerful optimization algorithms, our customers can place complex shapes in such a way that material is used to the maximum and waste is reduced to the minimum. All variables are evaluated, the print jobs in the queue are analyzed and the best combination is determined for the automatic creation of collective forms across customers and orders. And it does this extremely quickly. This means that our customers always achieve optimum efficiency when grouping their print files.

The advantages with intelligent nesting software from OneVision

The intelligent setup of print forms for your decisive competitive advantage:

- Supports all classic nesting tasks: free-form nesting, guillotine nesting, matrix nesting, sub-nesting

- Optimal material utilization and clustering according to customer requirements

- Enormous saving of working time compared to manual placement

- Maximum machine utilization and faster throughput times

- Consistently high quality standards

Unique nesting software technology: precise and extremely fast

Finishing and cutting are very important components of nesting/gang run printing because they determine which method is used for nesting and which other time-saving technologies can be used.

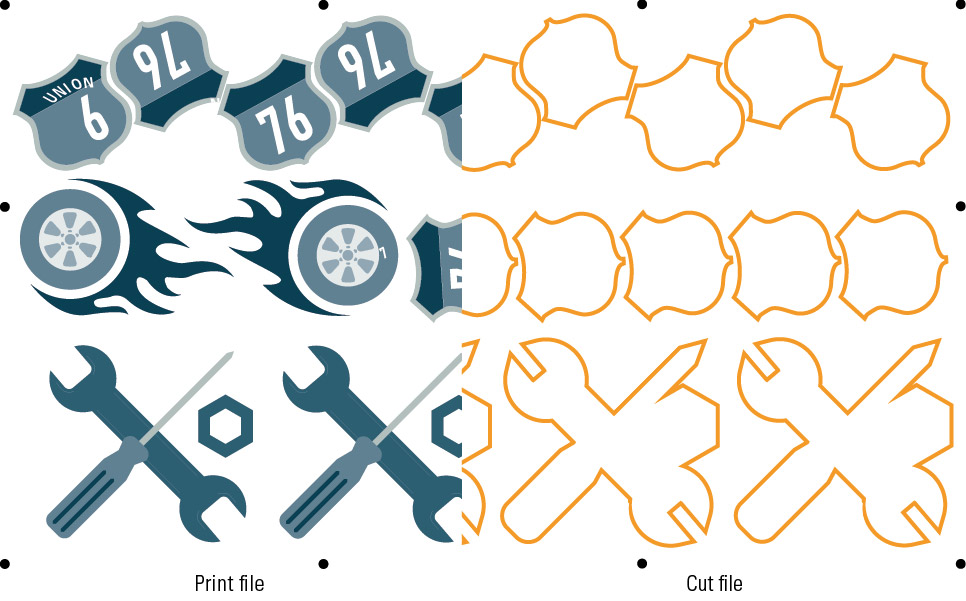

Although it may sometimes be necessary to nest on the basis of the trim box (the final format of a PDF file), nesting is usually performed on the basis of the cut line, so the generation or detection of this is very important.

It is important that the nesting software supports the fully automatic detection of cutting lines, the closing of incomplete cutting paths and, if possible, the merging of cutting lines. This is also called "common line" technology and can dramatically reduce cutting times. Ideally, as with OneVision, this is done fully automatically based on the detection of adjacent pixel values.

If missing bleed is also a recurring issue in your prepress department, OneVision Software has a practical, automated solution:

Find out more about full-bleed printing on this page.

In a fully automated, modern, flexible and dynamic workflow that uses ganging for printform creation, a nested print file and the associated cutting line file with all identifying elements, such as barcodes and register marks, are always generated simultaneously.

In the video on the left, you can see how individual artworks are automatically nested after being copied into a hotfolder, including pre-repair of the cutting lines (name or outline of the cutting line are fixed). The nesting software generates a file for printing and a second file for the cutter. On the right in the video exactly the same happens, but manually. The disadvantages are mainly the time taken, but also the utilization of the substrate.

Nesting/gang run printing as an element for the automatic creation of a prinform is a very individual, powerful, and increasingly important tool. Especially in today's extremely competitive print service provider environment, it offers the possibility to create decisive advantages in terms of quality, speed, and overall reducing printing costs.

There's no shortage of possible connections/integrations with hardware suppliers – we've compiled comprehensive information on end-to-end print integration on this page.